Braking Systems

Basic explanation of braking systems

Brakes

It is often necessary to slow or stop a machine, and to do this in a controlled manner a brake is used. Most brakes are of frictional type, in which a fixed surface is brought into contact with the moving part which is to be slowed or stopped. The two surfaces rub together and energy due to the motion is converted into heat and dissipated to the atmosphere. The loss of energy from the moving part is accompanied by the desired reduction of speed.

Brake are generally of the rotating type, in which a block or band is pressed against a revolving drum or disc but there are also linear or straight-line motion brakes.

Band brakes

The band brake is a simple but very effective means of controlling motion, particularly with cranes and hoists where the load is always pulling in the same direction and must be held safely. It consists of a flexible brake band and wrapped around a drum which revolves as the machine operates. As long as the band is loose it has a little contact with the drum, which is able to revolve freely, but when the band is tightened it grips the drum firmly and develops a powerful braking force.

If the drum revolves so that it tightens the band as the brake is applied, the braking effect increases considerably, and the system is said to be energizing. This feature is found in different forms in other types of brakes, including some used on cars – it enables a larger braking effect to be achieved for a limited applying force.

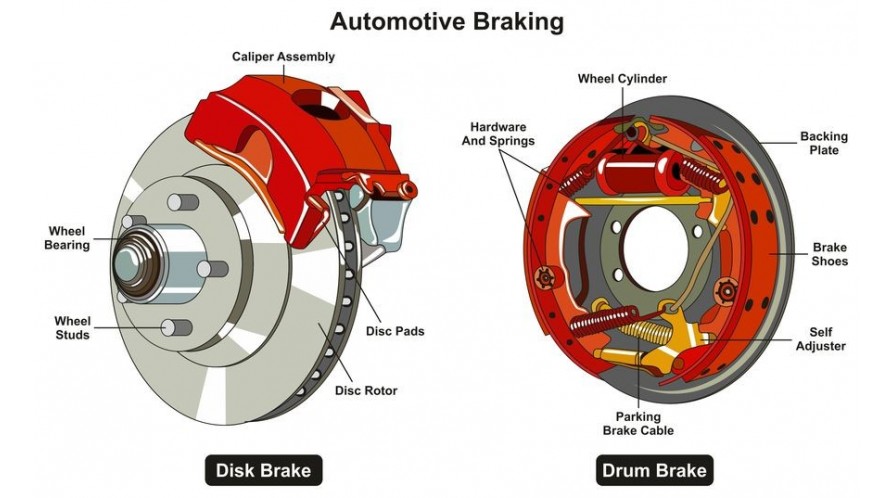

Drum brakes

In the internal expanding type of drum brake, two brake shoes on a fixed mounting are pushed against the inside of a rotating drum to create the required braking force. In some cases the shoes are operated mechanically but nowadays hydraulic or compressed air systems are often used for applying the brakes. Brakes of this type are widely used on trucks, buses and motorcycles; on modern cars they are usually found at the rear only.

The metal brake drum dissipates heat quite well, particularly if there are fins on its outer surface to increase the area for heat dissipation, but the internal forces created by the shoes can cause distortion which leads to cracking and failure if temperatures become excessive. Self-energizing types give powerful braking but their effectiveness falls off rapidly at high operating temperatures through what is called fade, where the higher temperature reduces the lining friction level. Drum brakes are also particularly liable to lose their effectiveness for a short period after immersion in water – after driving through a flood or a ford it is necessary to proceed cautiously and use the brakes frequently but lightly until they dry out.

On a typical drum brake, one shoe is self-energizing and the other is not. As the drum rotates it tends to pull one shoe harder against the inner surface, so that the braking effect is increased: this shoe is called the leading shoe. The other shoe is pushed off by the drum and its braking effect is reduced; this is called the trailing shoe. The leading shoe will wear faster because it does more work than the trailing shoe.

To gain particular advantage of power or wear resistance, drum brakes have also been designed with two leading shoes, with two trailing shoes or with three or even four shoes.

The power of car brakes must always be matched to the load carried by each axle and there is also the effect of weight transfer from rear axle to the front axle during normal braking. Cars usually, therefore, have more powerful brakes at the front, and, because more energy has to be dissipated, these are often disc type rather than drum.

Disc brakes

The disc brake consists essentially of a revolving disc which can be gripped between two brake pads. The calliper type brake commonly found on bicycles is a familiar example but disc brakes for cars are hydraulically operated and the pads cover between one sixth and one nineth of he swept area of the disc. Because the disc is less prone to distortion than a brake drum it can run at much higher temperatures without ill effect; the disc brake can therefore be used for much heavier duty than a drum brake provided an appropriate grade of lining is used.

Disc brakes are now used extensively on the front axle of cars where, within given size of wheel, they dissipate about twice as much energy as the rear brakes. High performance cars sometimes have disc brakes on both axles. A rather different design of disc brake, having linings equal in size to the full swept area of the discs, is sometimes found on tractors.

Conventional disc brakes are not self-energizing; to achieve the required braking force very large hydraulic pistons must be used together with a large master cylinder to provide sufficient fluid flow. This would, in many cases, lead to excessive pedal efforts, so many disc braked cars have a brake servomechanism to assist the driver.

All cars need a parking brake which is mechanically operated. Although this commonly acts at the rear, in some cases it acts at the front wheels. When the parking brake is on a drum braked axle it usually operates the same shoes that are controlled by the foot brake system; when disc brakes are involved, the parking brake often has its own pads in an attachment to the main brakes.

Antilock braking system

Conventional braking systems on cars have one major disadvantage – if the driver uses the brakes too hard on a slippery road, the wheels will lock and the car may go out of control. To solve this problem, some cars now are fitted with antilock braking systems. These systems can sense when one or more of the wheels is about to lock and reduce the braking effort to that wheel. Some earlier antilock systems used mechanical sensors to detect wheel-lock, but now electronic sensors are used to monitor the speed of each wheel and the information is processed by a control unit which adjusts the braking effort at each wheel so that the maximum braking is achieved. The braking system itself still uses hydraulic pipes and pistons in just the same way as a car without antilock, so if the electronics in the antilock system should fail, the driver still has the same braking capability as in an ordinary car.

Brake materials

The material of which the rubbing surface of brakes are made must give a good level of friction or excessive force would be necessary. At the same time, the life of these parts must be acceptable for the class of application. Experience has shown that the best results are obtained when the moving part is of metal and the stationary parts are lined with a composition friction material which wears much faster than the metal but can readily be replaced.

For general use, such as on vehicle brakes, cast iron has been found to be the metal surface most suitable. Drums can be made of cast iron lining with a light alloy body for improved heat conductivity but these are expensive; discs can be made with internal air passages.

Brake linings for general use are made of a carefully chosen mixture of fibre, metallic particles and non-metallic ingredients bonded together with a temperature resistant synthetic resin, railway disc brakes use composition block brakes still mostly use cast iron blocks, although composition blocks are used, but railway disc brakes use composition blocks excessively.